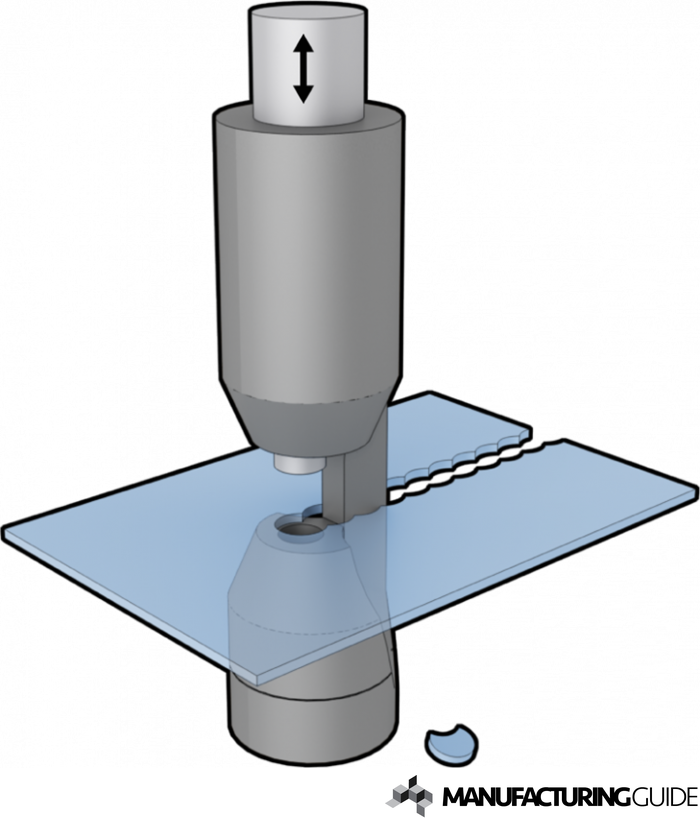

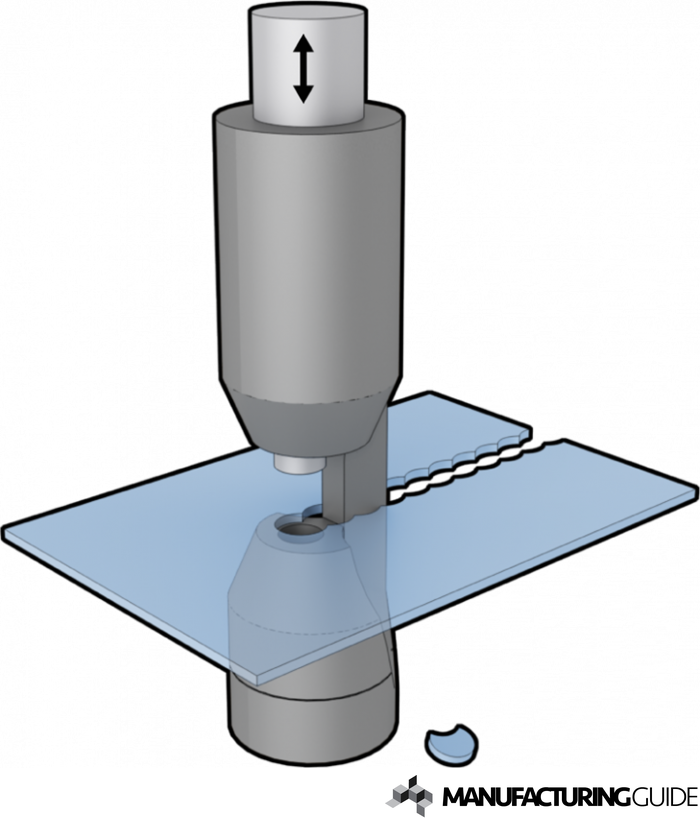

The nibbling process cuts a contour by producing a series of overlapping slits or notches.

Nibbling operation in sheet metal.

Nibbling operation to cut sheet metal part.

Are these sheet metal nibblers worth the money.

In sheet metal operations the metal is sheared hence also called as shearing operations.

Blank is the required product of the operation and the.

Blanking is a cutting operation of a flat metal sheet and the article punched out is known as blank.

A nibbler or nibblers is a tool for cutting sheet metal with minimal distortion.

By using nibbling operation complex shapes in sheet metal can be cut using simple punches round or rectangular punches.

This allows for complex shapes to be formed in sheet metal up to 6 mm 0 25 in thick using simple tools.

Rapid make paradise brand sheet metal nibbling machine available in three models pn 3 pn 5 pn 8.

These machines can be used in sheet metal cutting solutions nibbling cutting attachments jigsaw attachments etc.

We give a quick review of it s ease of use and quality.

Nibbling operation in sheet metal nibbling process involves cutting of sheet metal parts by using a series of overlapping punches.

Fine blanking is an advanced precision pressworking process that can create cuts having close tolerances and straight smooth edges without shaving or other secondary processes.

Find the nibbler here.

The paradise pn series sheet metal nibbling machine is a rugged sturdy reliable multipurpose machine capable of many sheet cutting forming operations.

Notching is a piercing operation that removes material from the edge of the workpiece.

As one of the renowned manufacturers and exporters we are involved in providing a qualitative range of nibbling machines to our valued clients so that they can find the best product from the market.

Another type operates similar to tin snips but shears the sheet along two parallel tracks 3 6 mm apart rolling up the waste in.